The IFC Classification Problem

Most project teams struggle with a fundamental openBIM challenge: how do you consistently classify building elements across 100+ IFC classes when most team members aren't BIM experts?

The consequences are significant:

Time Drain

Manual classification consumes 50-80% of model preparation time. Contractors routinely reclassify entire models between design stages.

Quality Issues

Misclassified elements create incomplete clash detection sets, inaccurate quantity take-offs, and coordination failures that propagate into construction.

Knowledge Barrier

The IFC schema's richness becomes its limitation—only technical specialists can leverage its full potential, forcing teams toward oversimplified models.

Cost Impact

Classification errors lead to rework, material waste, disputes, and lost trust in digital workflows.

Why traditional methods fail:

- Manual expert classification doesn't scale.

- Simple heuristic rules (identifying only beams, columns, walls) miss 90% of the IFC schema's value.

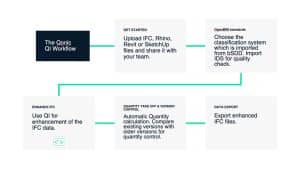

How QI Works

Simple Workflow:

- Upload IFC file or native format (Revit, Rhino, SketchUp)

- QI analyzes at 100+ objects/second

- Review top 5 classification suggestions with confidence scores

- High-confidence predictions auto-apply; uncertain cases prompt validation

- Corrections improve future classifications automatically

Real-Time Intelligence:

- Visual feedback shows classification reasoning

- Confidence scores indicate reliability

- One-click corrections for user control

- Client-side processing ensures data privacy

Time Savings

Faster model preparation for coordination and quantity take-offs

0%

Process Efficiency

- Vendor-agnostic: Works with 5+ authoring tools plus mesh geometry

- Scalable: Validated on federated models across all disciplines

- Energy-efficient: Client-side processing (<25MB) vs. cloud AI

Quality Improvements

- 98% accuracy even for ambiguous geometric shapes

- Measurable reduction in BCF coordination issues

- Complete clash detection sets through automated validation

Cost Reduction

- Eliminated repeat classification across disciplines

- Reduced construction rework from early error detection

- More reliable cost estimates from consistent quantity data

Sustainability Impact

- Lower carbon footprint from reduced rework and material waste

- Energy efficiency through compact, client-side models

- Extended data lifecycle with properly structured IFC models

What Made This Work

- Standardization enables AI — IFC's consistent structure was essential for training reliable models

- Purpose-built beats generic — Domain-specific architecture outperforms adapted solutions

- Real-world training matters — 8M+ elements from actual projects ensured robustness

- Continuous learning prevents obsolescence — Dynamic architecture stays current as technology evolves

- User feedback accelerates improvement — Corrections create a virtuous cycle

Critical Success Factors

- Build on open standards from day one

- Invest in domain expertise, not just data science

- Design for edge cases and imperfect data

- Make AI decisions transparent to build trust

- Create feedback loops for continuous improvement

Lessons for Your Organization

For Technology Developers:

Start with openBIM standards—proprietary approaches limit scale and lock users into specific ecosystems

For Project Teams:

Adopt classification validation early, before errors propagate downstream into coordination and construction

For Industry Leaders:

Recognize that AI doesn't replace expertise—it democratizes technical knowledge across entire project teams

Stakeholder Voices

About This Case Study

buildingSMART International publishes case studies to demonstrate the real-world value of openBIM standards and services including IFC, IDS, BCF, and bSDD. We showcase diverse implementations to inspire innovation and guide adoption.

Featured in this case study: Qonic NV (Belgium)

buildingSMART International does not endorse specific commercial products. Company information is provided for educational context. Organizations interested in similar approaches should evaluate multiple solutions and consult with openBIM professionals.