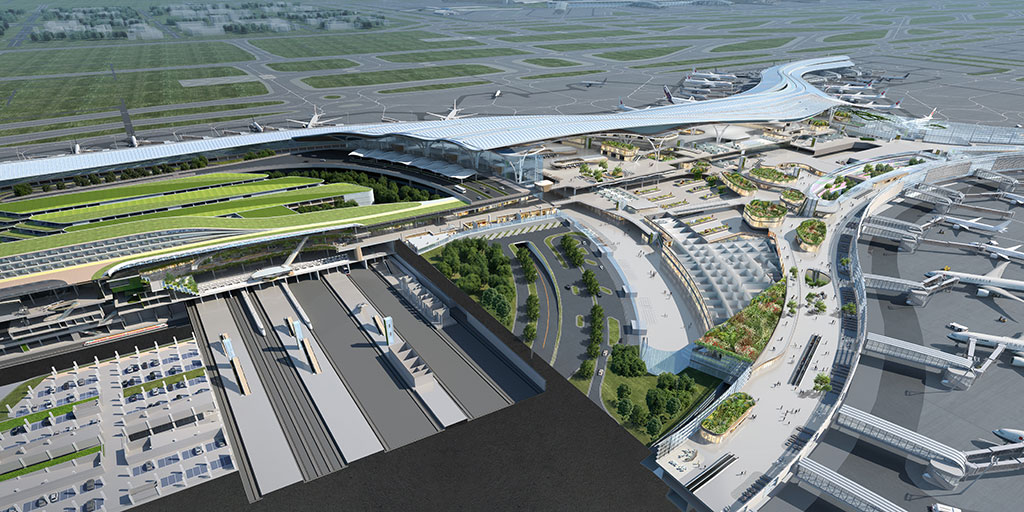

Coordinating China's Largest Airport Expansion

How do you coordinate 200+ organizations from 4 countries and regions, managing over 25,000 builders across a 5-year construction timeline while ensuring seamless data exchange across 10+ specialized disciplines?

The Scale Challenge

- Investment exceeding ¥53 billion yuan

- Multiple specialized contractors across architecture, structure, MEP, civil works

- Government mandate for BIM intelligent construction implementation

- No precedent for digital coordination at this scale in Chinese civil aviation

The Standards Gap

When the project began in 2020, China's national BIM standards only covered basic areas like delivery, classification, and data storage. Critical gaps existed in information management, data dictionaries, and automated compliance checking—insufficient for a project of this complexity.

The Coordination Problem

- Data exchange between hundreds of different software tools

- Consistent classification across diverse international teams

- Real-time collaboration during construction

- Quality control across massive federated models

- Traceability from design through operation and maintenance

Why traditional approaches fail:

- Proprietary file formats create data silos.

- Manual coordination doesn't scale.

- Inconsistent standards lead to rework and costly conflicts discovered too late.

An Integrated openBIM Ecosystem

ISO 19650 + openBIM

The project established:

- Asset Information Requirements (AIR) for operational needs

- Project Information Requirements (PIR) for delivery goals

- Exchange Information Requirements (EIR) defining what, when, and how information is delivered

- Information Delivery Manual (IDM) specifying workflows

- BIM Execution Plan (BEP) coordinating all parties

Collaboration Efficiency

- 45+ software tools working together through IFC interoperability

- 200+ organizations coordinating seamlessly across disciplines

- 5,118 IDS validations ensuring data quality automatically

- 3,190 BCF issues tracked and resolved systematically

Cost Savings

- ¥2.6 million saved in preliminary design through spatial optimization

- ¥4.53 million saved through BIM-assisted scheme optimization

- ¥46.6 million saved to date (estimated ¥128.6 million upon completion) through structural conflict resolution

Design Quality Improvements

- 1,500+ conflicts resolved before construction

- 119 instances of slab depression coordination

- 201 annotation corrections

- 158 reservations and embedment conflicts

- 157 collision resolutions

Construction Efficiency

- 80% of steel components digitally fabricated with 2% reduction in material loss

- 520 tons of support steel saved through IFC-based crane installation optimization

- 30 days shorter assembly period with reduced high-altitude work safety risks

- 50% reduction in rebar losses through BIM-guided cutting

Intelligent Construction Performance

- 5-8x efficiency with wall plastering robots vs. manual work

- 545 m³/h pavement construction rate (100%+ improvement over traditional methods)

- 20% improvement in process quality control

- 50% overall efficiency gain in airfield construction

Sustainability Impact

- Material efficiency: 50% reduction in rebar waste, 60% decrease in labor demand, 40% reduction in rebar inventory

- Carbon tracking: Optimized material selection and tracking using QR codes and RFID

- Environmental monitoring: Real-time dust level monitoring with automated water mist activation

- Climate adaptability: Enhanced through wind environment simulations

The project demonstrated that successful BIM implementation relies on four critical elements:

- Well-defined information requirements and response measures

- Standardized exchange methods and schemas

- Sufficient and structured data resources

- Secure and reliable data-sharing environment

Only when these elements align can data truly deliver value across project lifecycle.

Critical Success Factors

- Adopt international standards early: ISO 19650 and openBIM standards provided proven framework

- Customize thoughtfully: Aviation-specific bSDD extensions addressed industry needs without breaking interoperability

- Automate validation: IDS toolkit transformed manual checking into automated quality assurance

- Integrate intelligently: Connected openBIM data with smart construction devices for 5-8x efficiency gains

- Maintain openness: 45+ software tools worked together because standards enabled interoperability

Where openBIM Required Further Development

- The project team identified areas for continued advancement:

- Data dictionary expansion — Continue building industry-specific bSDD content and semantic networks

- IDM and IDS libraries — Develop reusable patterns to accelerate future projects

- CDE enhancement — Improve alignment with stakeholder interests and explore Large Language Model integration

- Automated Rule Checking — Advance beyond validation into automated compliance and control

Stakeholder Voices

About This Case Study

buildingSMART International publishes case studies to demonstrate the real-world value of openBIM standards and services including IFC, IDS, BCF, and bSDD. We showcase diverse implementations to inspire innovation and guide adoption.

Featured in this case study: Guangdong Airport Authority

buildingSMART International does not endorse specific commercial products. Company information is provided for educational context. Organizations interested in similar approaches should evaluate multiple solutions and consult with openBIM professionals.